Providing continued excellence, quality, sustainability, and reliability of service, as we work with you to implement, optimize, and achieve your goals.

Our main markets are consumer devices, medical and esthetical industry, telecom, and communication, automotive, semiconductor, home appliances, defense and aerospace industries.

An accomplished team of talented, dedicated, experienced professionals, committed to your success.

Incorporating 50 years of expertise in innovation and excellence, and a proven track record of long-term partnerships based on mutual commitment and trust, for rapid solution turnaround through a uniquely customer-centric approach, at unparalleled prices.

Our team of experienced expert engineers custom design a solution to meet your individual needs.

Our team of experienced expert engineers custom design a solution to meet your individual needs.

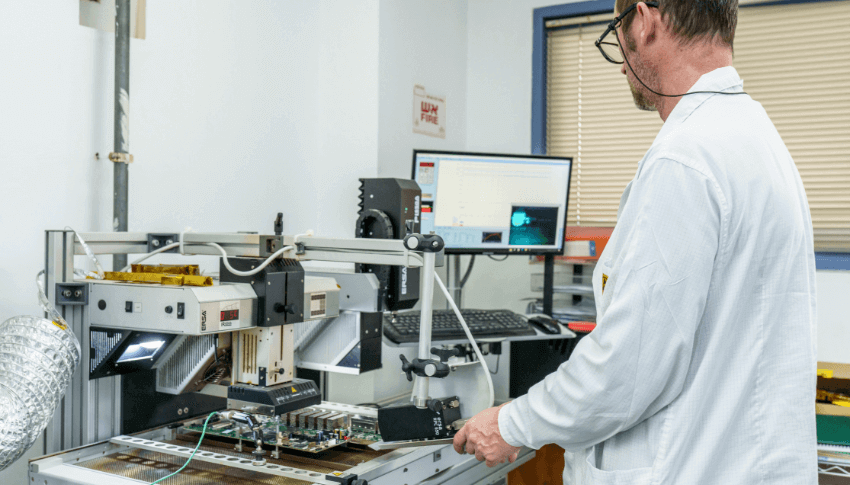

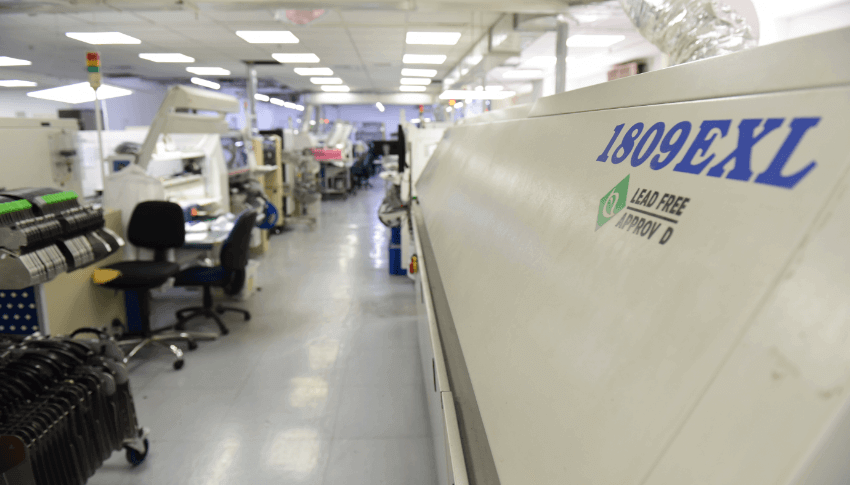

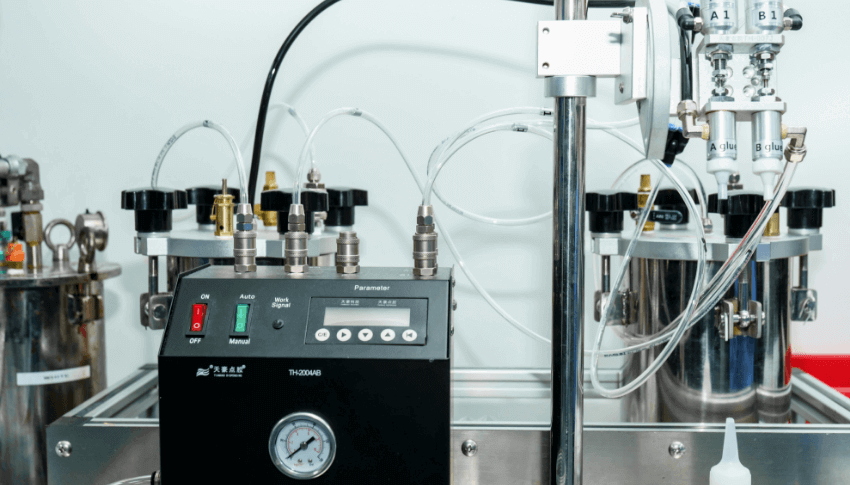

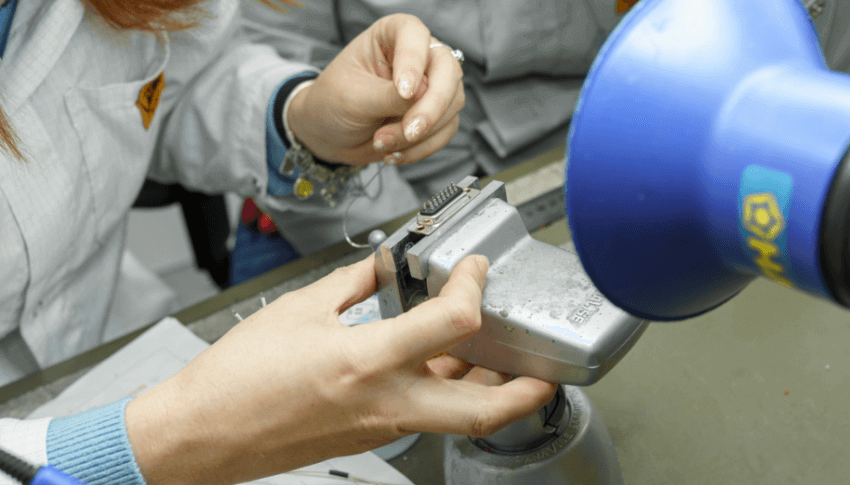

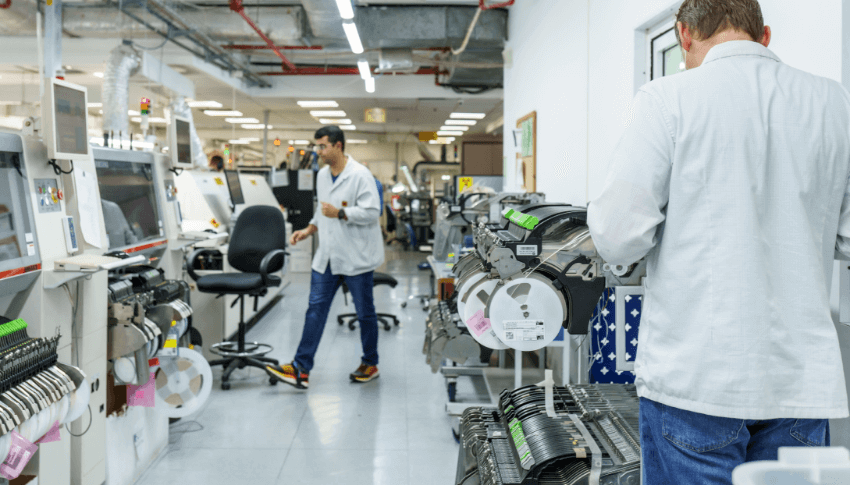

We manufacture your concept with our innovative manufacturing technologies.

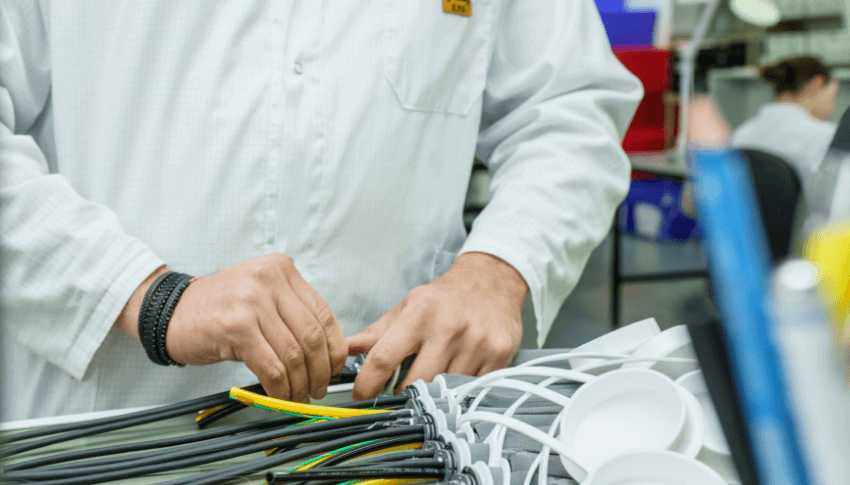

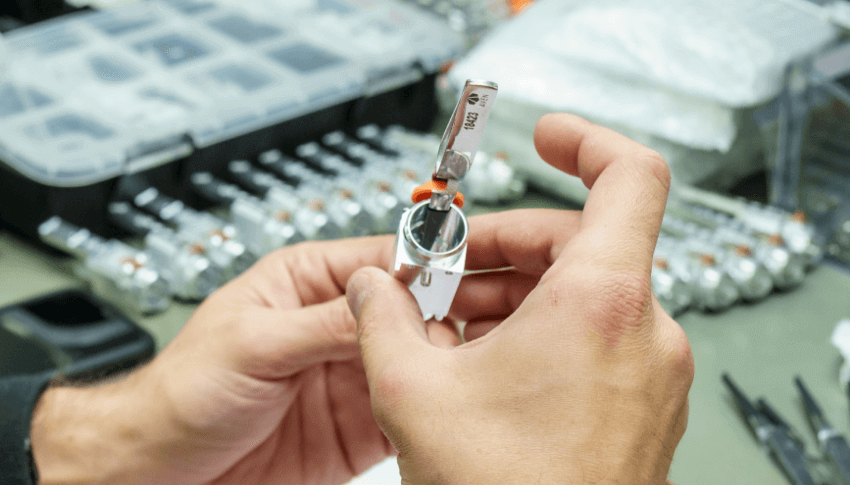

We manufacture your concept using any of our nineteen innovative manufacturing technologies,

in seven sites.

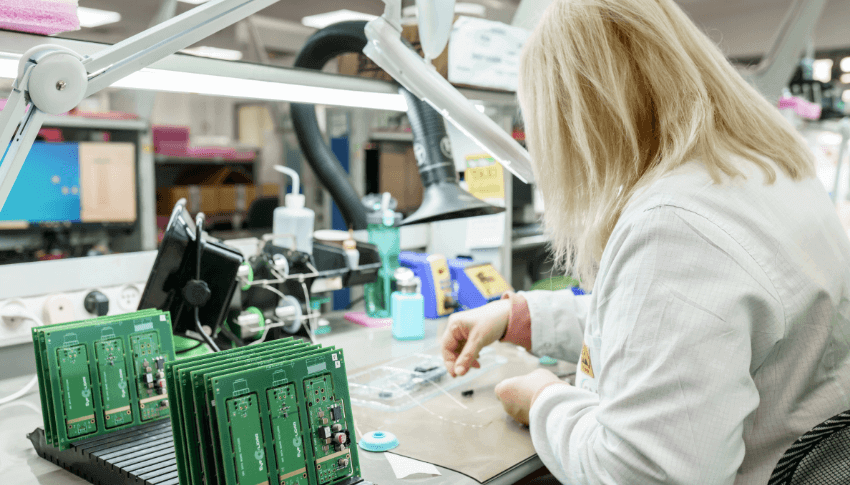

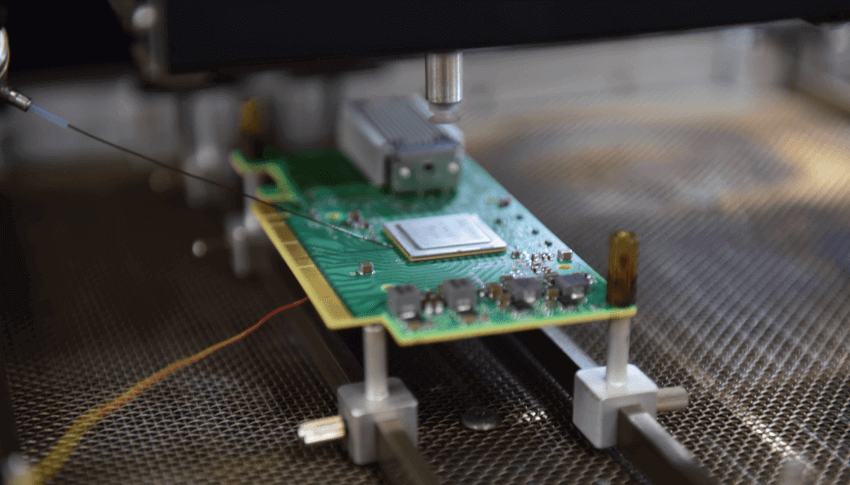

We take your product idea and assemble it for you, via our extensive range of SMT capabilities and system integration.

We take your constructed product and assemble it for you, via our extensive range of SMT capabilities and system integration.

We deliver your product on-site, directly to your place of business, quickly, and with first-class execution.

We deliver your solution on-site, directly to your place of business, quickly, and with first-class execution.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Nunc faucibus a pellentesque sit. A cras semper auctor neque vitae tempus. Scelerisque varius morbi enim nunc faucibus.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Nunc faucibus a pellentesque sit. A cras semper auctor neque vitae tempus. Scelerisque varius morbi enim nunc faucibus.

We offer seven core services to ensure that you are fully taken care of, from the start to finish. Our specialized departments include: Engineering, Innovation Center, Customer Focus Team, Quality Control, PCBAs/Box Build/System Integration, Logistics, Quality & Procurement.

Wherever you are with us on your journey, we’ve got you.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Nunc faucibus a pellentesque sit. A cras semper auctor neque vitae tempus. Scelerisque varius morbi enim nunc faucibus.

Atena Ltd.

POB 257, Nesher, 3688808, Israel

All rights reserved to Atena Integrating solutions Ltd. 2023

Privacy Policy | Terms and Conditions

UI/UX Design by Now Branding